Manufacturing is a practice that has been around for a while and it has become a very important source of income. In today's global world, manufacturing involves many different steps from initial conception to final production of the product.

There are also many tools involved in manufacturing making it possible for you to have the products that you need. Below are six tools used in manufacturing and how they are important for our everyday life.

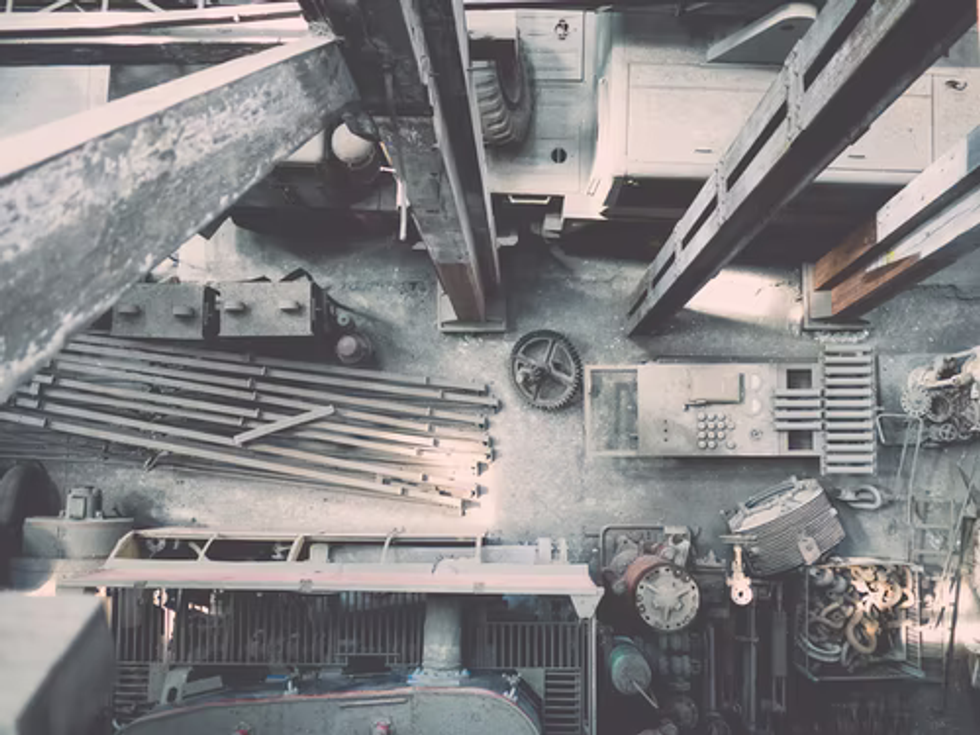

Bucket Elevator Conveyors

The first tools used in manufacturing are bucket elevator conveyors. You can search for manufacturers websites there, you can find bucket elevator conveyors for sale if you want to buy directly from them. They are important because they help to lift materials from one level of a plant to another. There are many types of bucket elevators including portable, self-supporting, non-self supporting, and jib type. These elevators have different uses depending on the type of material being transferred from one level to another.

Bucket elevators and conveyors are very similar and work the same way. However, bucket elevators have a different shape than conveyors which enables them to carry more materials at once. Bucket elevators are also attached to a chute which can open and close depending on the size of the materials being moved. This makes it possible for the material to be deposited in different areas.

The capacity of bucket elevators is measured by the number of buckets that can be carried on the elevator. Bucket elevators are capable of carrying materials that weigh more than 100 pounds each. Materials such as rocks, coal, and grain are moved with this type of elevator at industrial plants. Conveyors are not used to transporting these types of materials. Instead, conveyors are used to moving different types of materials that do not weigh more than 100 pounds. These materials include automobiles, foodstuffs, and paper products.

One of the most important parts of a bucket elevator is the chute that holds material as the bucket ascends and descends. This chute includes a gate at the bottom which can be opened or closed depending on whether large or small materials need to be moved. The gate is movable and can be moved to the side when materials are needed. When it is time to move large materials, the gate is raised which enables the bucket elevator to carry more material. The size of a chute will vary depending on what type of material needs to be carried by this specific bucket elevator.

Robots In Manufacturing

The second tool used in manufacturing is robots. Robots are often called automated guided vehicles (AGVs) and they help to automate the process of moving materials from one place to another within a factory. These robots carry components such as aluminum, iron, wood, and plastics allowing for faster production rates and ease of use.

Robots often work in conjunction with other tools such as AGVs and bucket elevators. For example, a robot could pick up apart from one conveyor belt and place it onto another to be used later.

This would not be possible without a bucket elevator. Bucket elevators carry materials from one floor to another within a factory. The earliest form of the bucket elevator was created by an English engineer, Peter Fairless in 1832. He used a steam engine that was connected to a series of buckets that traveled along an iron track. In 1843, Reuben H. Swayne of New Jersey patented a similar design that was not connected to a steam engine. His design used two tracks which each had its own set of buckets and both tracks could move materials independently (one up, one down).

Robots and bucket elevators work together on the factory floor because robots do not have the capability to travel away from their station. The bucket elevator is needed to transport the material to the robot and this allows for a more efficient and productive workplace.

Control Systems For Manufacturing

Another great tool in manufacturing is the control system. Control systems are used often in factories and allow for ease of use and more precise movement of tools and machines. These systems create a complete flow within the factory so that each tool is used exactly what it needs to be.

The injection molding machine is an example of how control systems are used. The machine must have the precise speed at which the material is put in, the speed at which it fills and cools down, and finally the speed and consistency at which it ejects from the machine. Each one of these speeds can be programmed within a control system to help make manufacturing as efficient as possible. This way the machine operates at a pretty much constant rate and does not have to slow down or speed up throughout its time being used.

These systems also allow for the development of sensors that interact with other tools within the factory. The injection molding machine can be connected to a robot arm so that as it is filled it tells the robot arm to grab onto the part and place it within a storage area. This allows for the two machines to operate together and not interfere at all with each other's processor speed.

GPS (Global Positioning System)

Global Positioning System (GPS) is an efficient tool in manufacturing. This tool is used to track the location of objects and people. The GPS has become increasingly important in manufacturing because it helps save time, minimize errors, and create an accurate record of everything that happens within a plant.

CAD (Computer-Aided Design)

The CAD is an essential part of any manufacturing process because it helps the product idea to become a reality. This tool is especially important when working with CNCs and other automated machines. The CAD can help design a product, view it from many different angles, cut the material to fit the product, and create blueprints for each component needed to build the final product.

The CAD and digital prototyping help to reduce the gap between idea and production by allowing for easier visualization of a design before it ever becomes a reality. This tool often cuts process times so that more products can be created in less time.

Computer Numerical Controls (CNC) For Manufacturing

A Computer Numerical Control is a device that is used to help automate the production of a product. These CNCs have the ability to read in certain programs and move around tools such as mills, lathes, saws, drills, or plasma cutters to complete a task.

A programmer writes a program for a particular operation and the computer numerical control then creates the tools to cut, drill, or shape materials. The user first programs the CNC by entering a series of instructions into a computer that tells it how many times it should cut, move, drill, etc. Once the program has been written and executed on the computer, all you must do is load your material and press "start". This device helps to speed up manufacturing by creating parts in a fraction of the time it would take an operator.

Computer numerical controls can create more complex parts with less human error involved. The computer numerical control moves around precise tools in order to get an exact measurement of the material. This process allows for more exact high-quality part creation, which ultimately lowers the overall cost of production.

CNCs are purchased by large corporations that have the capital to invest in this type of technology. These companies then install the CNC into an existing factory that already uses tools like lathes, mills, or saws to create their parts. Once the CNC is installed it must be programmed specifically for each part it will make. The programmers who write these programs need extensive training and knowledge of the machine that they are writing the program for.

Compared to other manufacturing methods like welding, cutting, or drilling the programming of computer numerical controls is time-consuming and takes longer to create parts. However, after the CNC has been programmed it can run unattended by an operator which makes up for what it loses in production time. The amount of money saved by using a computer numerical control can be great.

Manufacturing is very important to our everyday lives. It involves many steps and tools that make it possible for profitable production. These tools mentioned above will help to make manufacturing run smoothly and effectively.